About Us

About Us

Your Trusted Electrical Service Partner

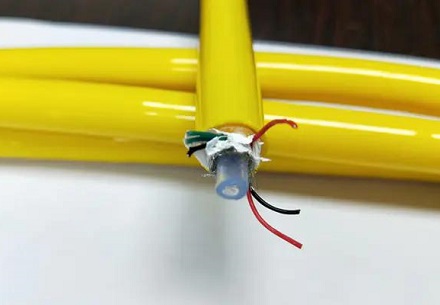

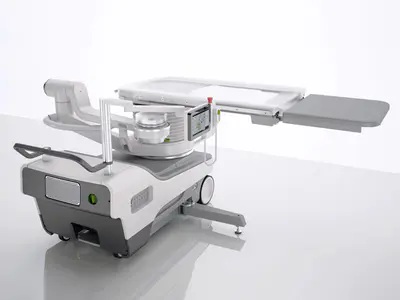

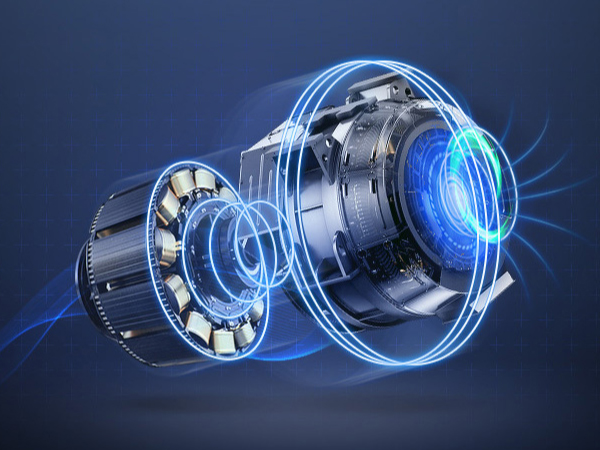

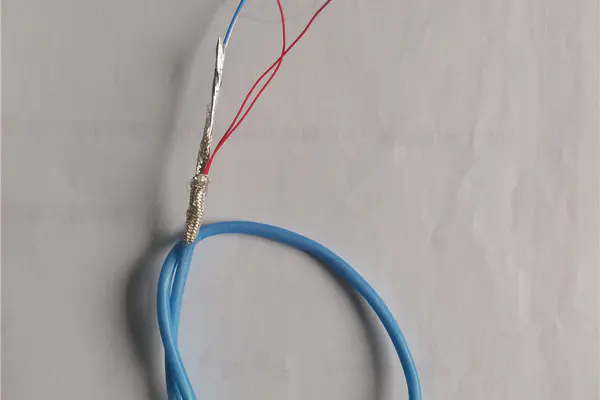

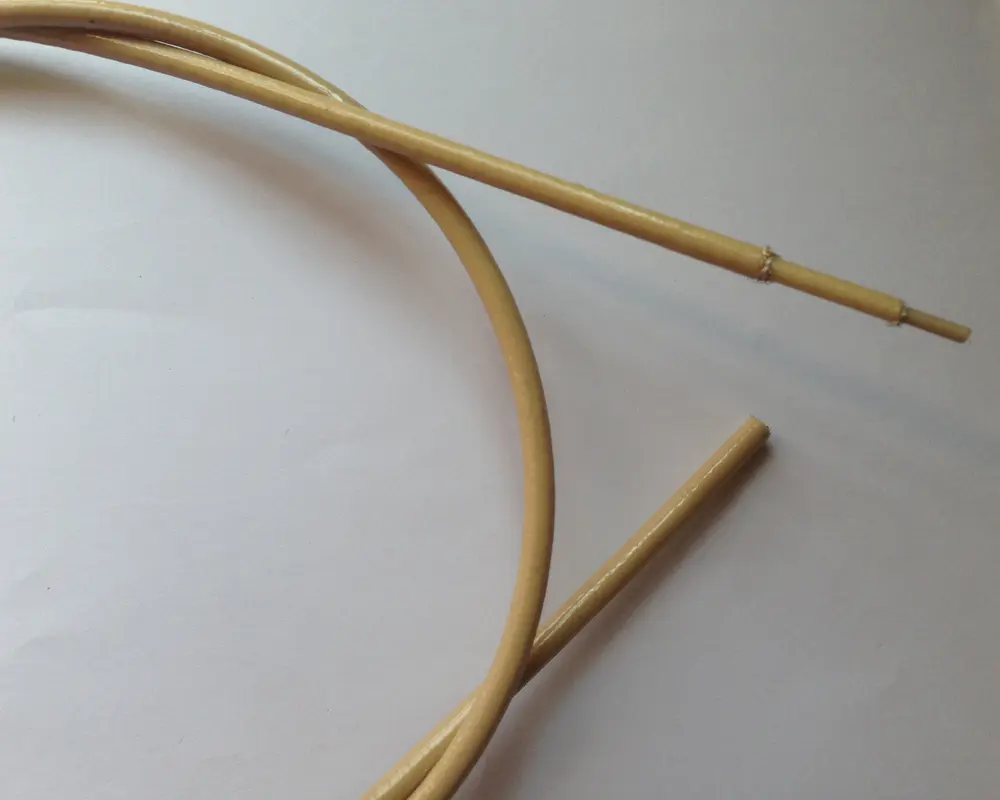

CITCable is a technology driven company who designs, manufactures and markets of High Temperature Sensor ,Fluid Resistant Automatic Transmission Wire ,Electronic transmission wire, Automotive primary anti-capillary cable, Fluid Blocking Engine/Transmission wire High Temperature Automotive ABS (anti-lock braking system)Sensor Cables , Electric Motorcycle Motor and Power Cables , Hot Oil Resistant 200°C Automotive Engine Wire , New energy EV Cable ,SPE Cable ,Military ,Civil radar system, Security system,Aerospace, Semiconductor automatic system,Ultra fine Medical Coaxial Cables and CMP/PLENUM/CL2P/CL3P cable products

Read More

About Us

About Us

Get a free quote

Get a free quote

IPv6 network supported

IPv6 network supported